Absorbable Implants

Aran Biomedical has significant expertise working with absorbable materials. As the market continues to incorporate more patient friendly solutions, absorbable polymers are becoming increasingly popular in next generation technologies.

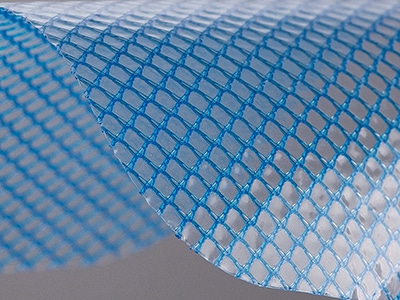

Absorbable Textiles

Whether braiding, knitting or weaving, Aran Biomedical has significant expertise manufacturing absorbable implantable textiles, such as absorbable mesh for hernia repair, absorbable sutures for sports medicine applications or implantable textiles for cardiovascular applications. Drawing on our biomaterials expertise, Aran Biomedical can tailor the material composition to meet specific customer requirements, such as biocompatibility, degradation time, and tensile strength. Selected yarns are characterised and carefully managed through fabric preparation, processing and post processing steps to ensure desired material properties are maintained throughout the development and manufacturing process.

As part of our full product service offering, parts can then be supplied, packaged and sterilised.

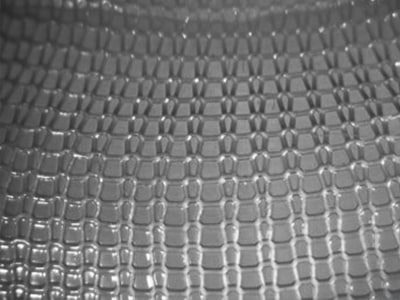

Absorbable Coatings & Coverings

Absorbable implants that degrade over time to be replaced by native tissue are increasingly sought as a preferred solution to the conventional non-absorbable alternatives currently available in the market. The integration of absorbable materials into implantable devices can also offer short term functional benefits for implantable devices. Aran Biomedical employs its biomaterials expertise, along with processing and materials handling capabilities to custom design these absorbable implantable solutions. Our solutions can be dip-coated or spray coated, allowing us to cover even the most complex geometries. Typical indications for resorbable coatings can include the creation of anti-adhesion barriers, or impermeable barrier layers.

Aran Biomedical also offer composite solutions, including resorbable coatings for braided stents or coated medical fabrics to support short term haemostasis.

Resorbable Polymers

Below is a list of some of the resorbable material that Aran have used in the development of implantable medical devices.

PL Poly(L-Iactide).

PC Poly(Ɛ-caprolactone).

PLC Poly(L-Iactide/Ɛ-caprolactone).

PLG Poly(L-Iactide/Glycolide).

PDL Poly(DL-Iactide).

PLDL Poly(L-DL Iactide).

PG Poly(Glycolide).

Resorbable Material Management

Materials are controlled through a comprehensive Quality Management System (QMS), to ISO standards, with activities carried out under cleanroom conditions. This ensures quality and trace ability from resin to finished device. In addition, Aran Biomedical uses the following systems to ensure consistent quality of resorbable materials:

- Degradation Control: Testing and characterisation of the material degradation profile is completed using viscometers and moisture titration equipment, while material quality during and after processing is maintained using vacuum ovens.

- Handing Facilities: resorbable materials are kept in cold storage and all units are vacuum sealed and packaged appropriately, to protect parts and maintain material integrity.