Scaffolds & Fabrics

Aran employs weaving, knitting and braiding textile processes, in the development of orthopaedic tissue engineering scaffolds and fabric. Leno woven devices are preferred, where a porous architecture with high longitudinal stiffness is desired. 3D knitted spacer fabrics are preferred, where a high degree of 3D interconnected porosity is desired, in a fabric of customisable thickness. Low profile 2D knitted and woven fabrics are preferred, for bone graft containment, dural repair, and minimally invasive tendon/ ligament repair.

Scaffold pore size and stiffness are typically customised, in collaboration with the customer, to facilitate regeneration of particular cell types e.g. fibroblasts.

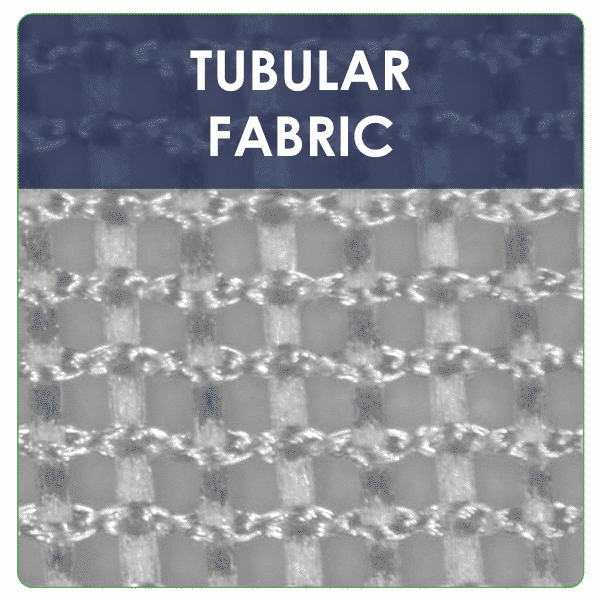

Knitted and woven tubular fabrics are used for bone graft containment. Materials include UHMWPE, PET, PP and PEEK, as well as resorbable material grades (e.g. PGA, PLGA, PLLA).

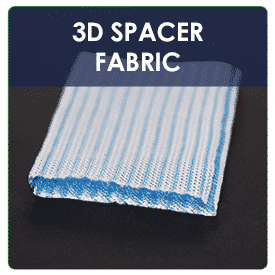

3D spacer fabrics enable development of tissue repair scaffolds in which considerable porosity is afforded to regenerating tissue. Scaffold pore size, strength and elongation can be closely controlled, at fabric design stage.

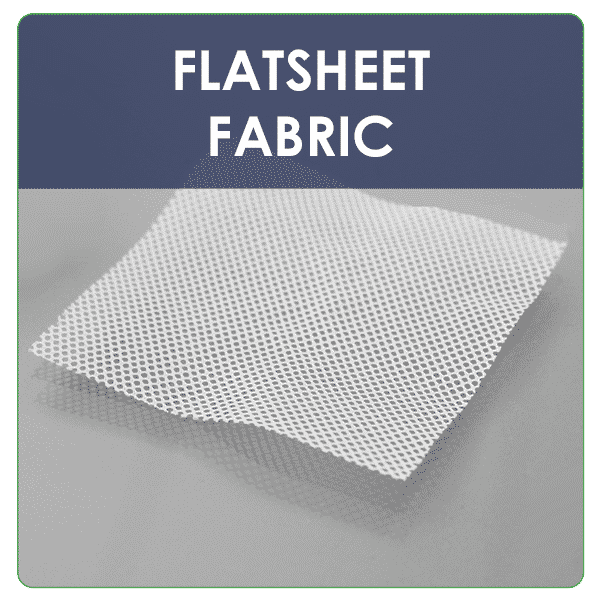

Knitted and woven fabrics (depending on preferred in-plane stiffness) can be produced with very small pore size to inhibit tissue integration, if preferred. Materials include UHMWPE, PET, PP and PEEK.

Dimensional properties (yarn thickness, pore size, fabric thickness, areal density) and mechanical properties (tensile and burst strength and stiffness, tear resistance) are tailored to the clinical requirement.

Fabrics with bifurcation can be produced, enabling a bilateral approach to soft tissue reinforcement and fixation.

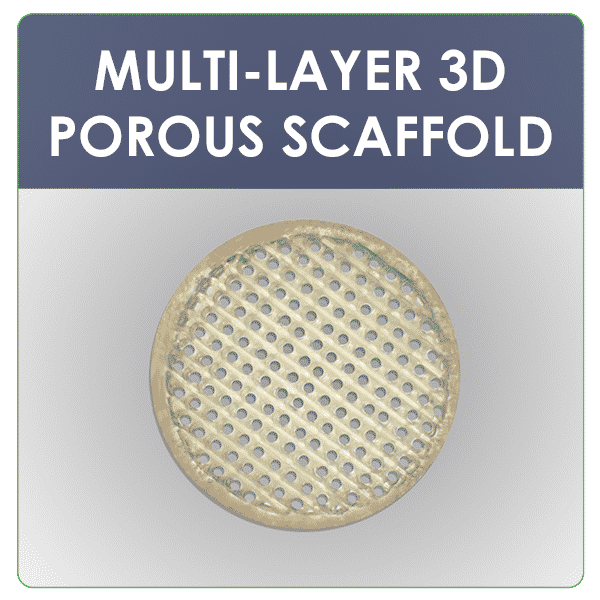

3D multi-layer scaffolds provide an interconnected porous architecture, which promotes tissue ingrowth, separate to whichever growth factors may be used in conjunction.