Suture Development Solutions

Custom sutures are developed in response to customer’s design inputs, incorporating seamless flat-to-round transitions, smooth tapers, loops and bifurcations, and porous architecture. Our suture offering extends beyond standard round braided sutures (USP 2 down to USP 7-0).

Suture clinical performance is tailored using appropriate material grade and textile design, leveraging Aran’s Textile Design Engineering expertise. Sutures are produced using implantable grade fibres of UHMWPE (e.g. Dyneema Purity), polyester (PET) and polypropylene (PP), as well as nitinol and resorbable polymers (e.g. PLGA).

High strength sutures are developed to standard USP specifications, incorporating multiple fibre materials grades as required to deliver strength and stiffness performance, colour coding, surface roughness and knot profile thickness

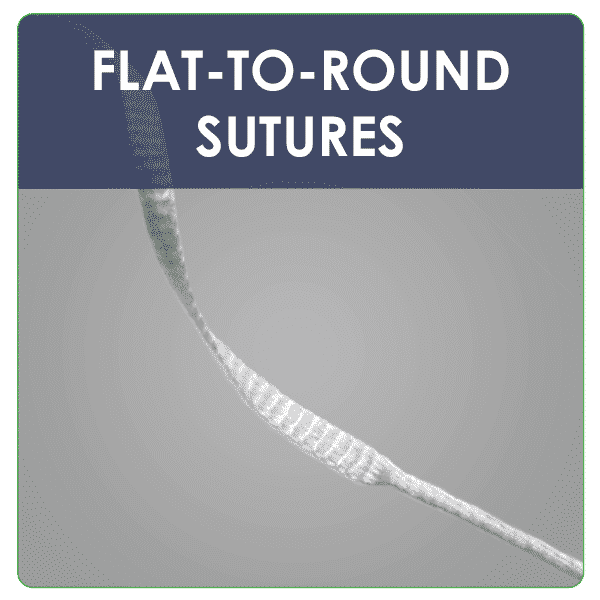

Flat-to-round sutures offer seamless transition from standard round USP specification (e.g. USP 2) to flat central section (e.g. 3 mm width), for reduced tissue contact pressure and pull through, whilst maintaining compatibility with standard instrumentation.

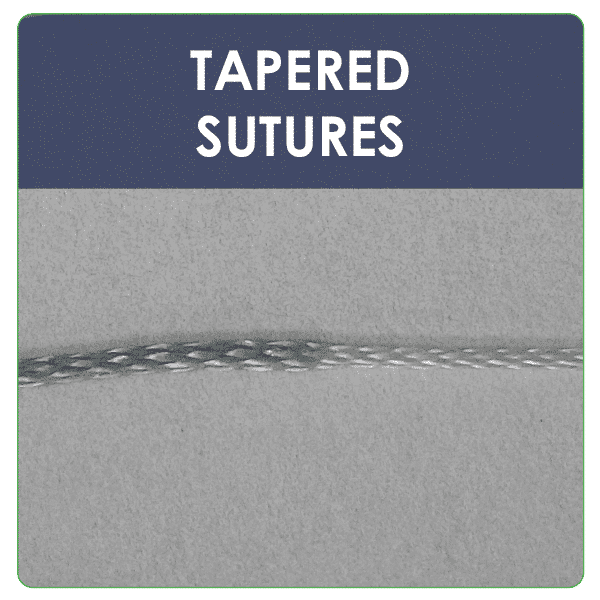

Tapered sutures are custom developed to user requirements, and typically contain regions of standard USP specifications, transitioning to thinner/ thicker regions, for the purpose of tethering or interference locking, as required by a procedure.

Aran develops resorbable sutures, with high initial strength, high strength retention, and low elongation. Resorbable sutures are typically braided in standard round or flat-to-round configurations.

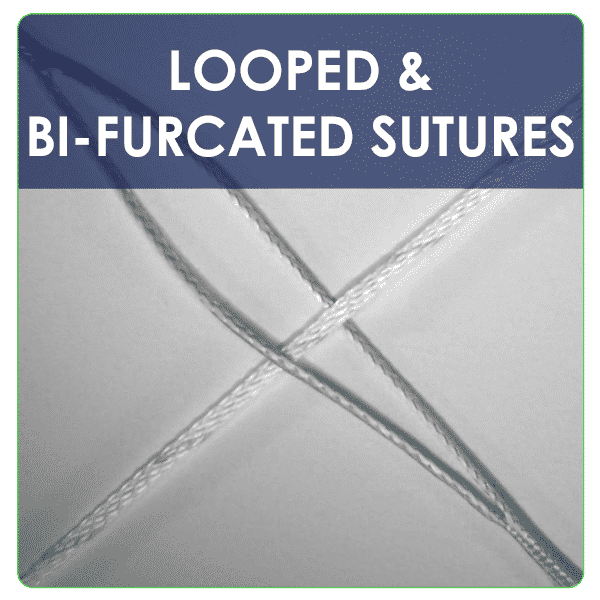

Looped & bifurcated sutures leverage Aran’s fully variable braiding capability, to incorporate features useful for tethering in non-standard product and procedural designs.

Your Content Goes Here