Weaving Capability Expansion at Aran Biomedical

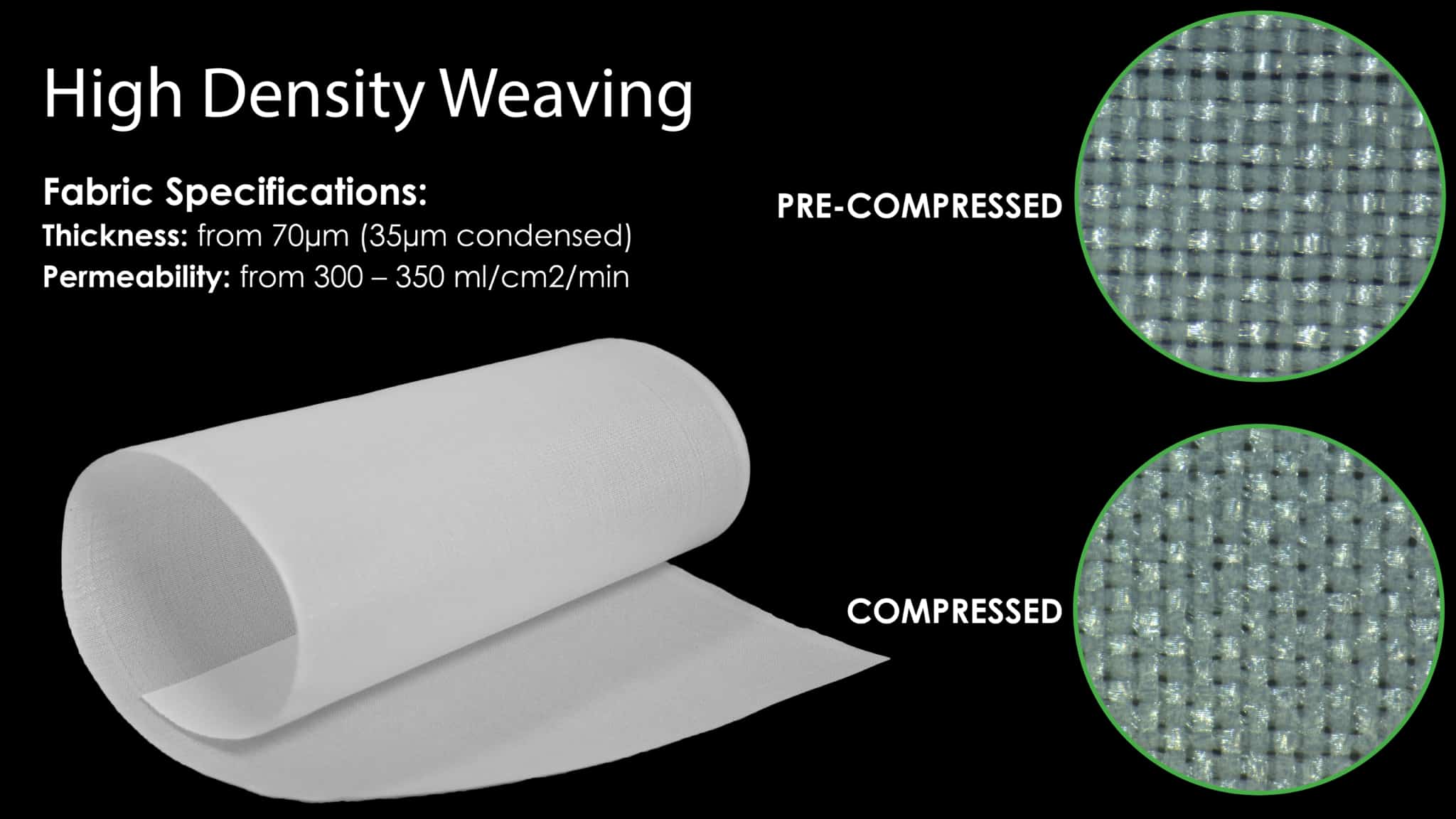

GALWAY, Ireland, December, 2021 – Aran Biomedical has expanded their weaving capabilities to include the condensing of high-density woven fabric. This technology breakthrough combines Aran’s existing compression techniques with dense woven fabric, allowing for the same material characteristics but with a dramatic reduction in thickness.

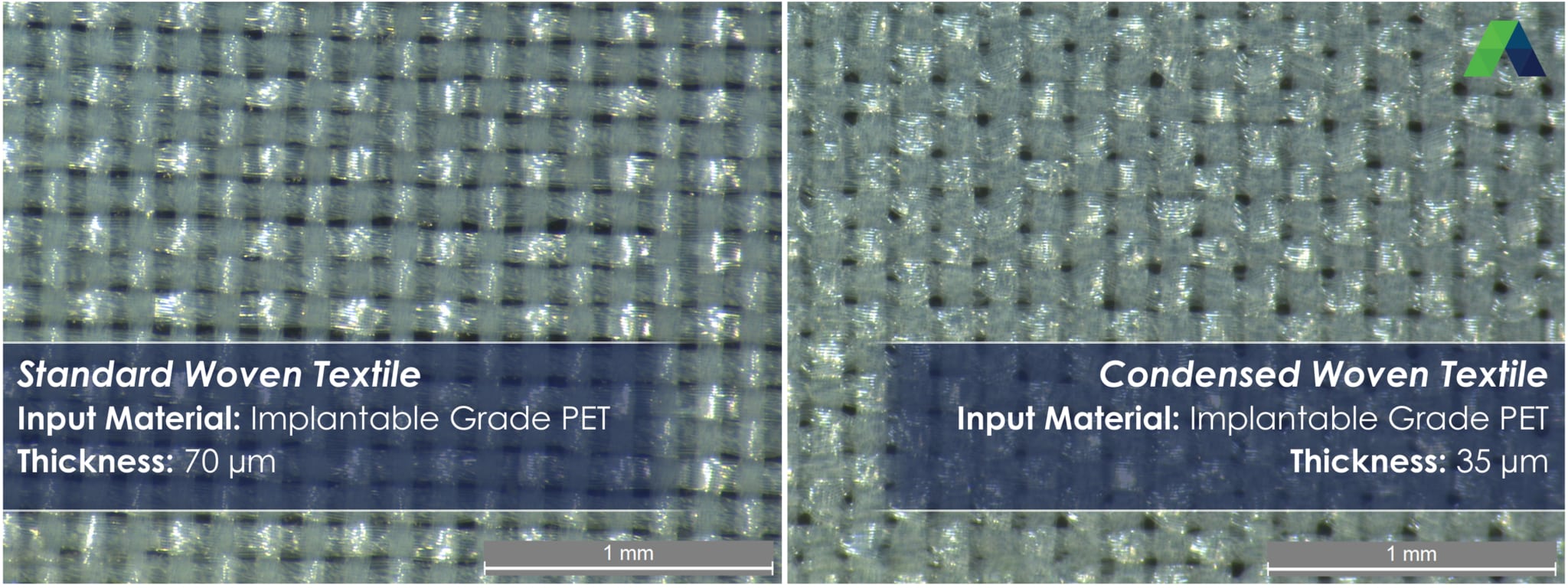

Condensed fabrics utilise a proprietary process developed at Aran Biomedical, to ensuring textile based finished devices and components are available at their lowest thicknesses. Our process typically leads to minimum reduction of 50%, but this can be as high as 70% depending on the configuration. An additional benefit of fabric condensing is reduced permeability as yarns flatten and spread out, without affecting the mechanical characteristics of the fabric. Woven fabric that has been condensed from 70 microns to 35 microns thick, shows a reduced permeability range between 300 – 350 ml/cm2/min.

These woven textiles are predominantly used in the structural heart and vascular spaces, more specifically for the development of heart valve skirts, occlusion devices, synthetic grafts, vascular stents, and endovascular devices. Aran Biomedical believes this new technology expansion will lead to further profile reductions in established devices and potentially lead to the development of more minimally invasive therapies in the space. This technology expansion compliments Aran Biomedical’s established platform technology, ValvTEX. This proprietary technique creates suture free textile covering for mitral, aortic, and tricuspid heart valves.

This Technology Expansion Allows For:

- Lower-Profile

- Enhanced Crimpability

- Wide Range of Implantable Input Materials

- Tailored Permeability

The image below illustrates the woven fabric pre and post compression. These images are of a densely woven PET structures which shows the pattern and overall weave structure remaining intact, despite the thickness being dramatically reduced by ~50%.

Our proprietary condensing technology is available across our full textile development portfolio i.e. knitting, weaving and braiding, and can be applied to an extensive range of input biomaterials including resorbable polymers.

Our Mission

At Aran Biomedical, our mission focuses on one key objective – Lowering the profile of our Customer’s device to enable more minimally invasive therapies. Everything we do and every new technology we bring in-house is done with this in mind.

About Aran Biomedical

Aran Biomedical Teoranta is a Galway based company that specialises in customised medical implant product solutions, with expertise in medical textiles, advanced braiding, elastomeric coating and PTFE encapsulation, as well as resorbable implants. The company offers a full-service solution, from design and development, to full-scale manufacturing of key components and finished devices, for world leading Tier 1 medical device companies who seek a trusted partner to help realise their product development needs.

Leave A Comment

You must be logged in to post a comment.