Implant Covering & Membrane Development Considerations

Implantable membranes are applied to implants that are used in multiple therapy areas, including cardiovascular, general surgery and orthopaedics, and the function of each cover varies by indication.

In this guide, we will look at some of the key considerations an engineer should be aware of when covering their implant, and talk through various covering options that can be considered.

Implant Covering Considerations/ Specifications

Implant Design

The design of the implant is the starting point for many covering projects, where a frame has been designed and now the team are looking to achieve their requirements by adding a cover. Frames range massively in geometry, material, surface properties and other dimensional attributes. However certain frame design features can inhibit the application of a coating or limit the number of covering options available.

- Applying a non-textile membrane to a frame, typically requires tooling to be developed that matches the frame geometry. If the frame is closed at both ends, such that a tool cannot be placed inside the frame, this can be a significant constraint. The option of closing one end of the frame after covering can overcome this issue.

- Braided or certain wire formed designs are not compatible with coverings that are cross laminated, as there is a likely risk that the material would shear off during crimping.

- Overlapping structures, such as a double layered or inverted braid, can create issues if applying a coated membrane. For example, it may be possible to coat the device, but if it is not managed correctly the device will not crimp or the material may shear off the frame during crimping.

- The combination of oblique shapes on a frame can limit covering options. For example, it may necessary to spray rather than dip coat the structure.

Determining a covering process that is compatible with your design is a great starting point.

Covering Objectives

The objectives of the covering will impact material selection. Requirements can range from creating an impermeable barrier/ managing permeability, enhancing tissue ingrowth, creating a hydrophilic or hydrophobic surface properties, enabling additional assembly etc. Having a clear checklist of items, in order of priority, is recommended, as engineers can find significant trade-offs in covering processes. These should include both functional requirements, along with mechanical/ performance requirements.

Crimp Profile

The delivery catheter size is a huge focus for minimally invasive devices. Any covering applied to an implant will increase its crimp profile, however the thickness of all covering options continues to reduce, so that the overall impact to profile may be limited to just 1 French size. It is important to recognise early on if your implant is likely to require a covering and allow for this in the design. Creating a more open strut configuration that allows space for the covering material during crimping can be helpful. Furthermore, avoiding sharp edges or points on the frame can avoid wear on the covering. Quantifying an acceptable covering thickness range based on your frame design and target delivery system and understanding what covering options are possible, is essential to ensuring success.

Biomaterial Selection

As outlined above, each covering material has its own characteristics and methods of application. Below we take a deeper look at some of the biomaterials Aran Biomedical work with currently and offer some insight in to their typical uses.

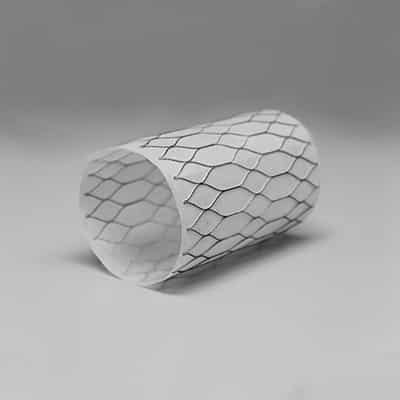

Implantable Medical Textile Covering

Textiles come in a range of configurations, including braided, knitted and woven. Knitted and braided components offer greater ability to conform to the frame, while woven fabrics can be made offer limited permeability. Textiles are sought after due to their controlled shape and stretch qualities, robust mechanical properties, including suture retention strength, general low profile and established clinical history.

The in vivo benefits of covering your frame with a textile include enhanced tissue ingrowth and controlled permeability. Textiles can also conform to the anatomy and the underlying implant, making them a preferred choice in AAA and TAA grafts, as well as heart valve skirts & covers, annuloplasty rings and high-strength tension chords and much more.

Elastomeric Coatings

Coatings are typically applied to the frame through a dipping or spraying process. This creates a smooth, uniform surface which is impermeable and has controlled elasticity. Applying a coating to the frame also allows for tailoring of surface properties. Typical materials used for implant coating include urethanes and silicones.

Some coated membranes can be as low as 5-10 microns in thickness, offering minimal impact to profile when compared to other covering options.

Elastomeric coatings can be found in retrieval, occlusion, delivery and embolic protection type devices.

PTFE Encapsulation

Polytetrafluoroethylene has a long-standing clinical history in medical devices. The biocompatible material is a preferred choice due to its hydrophobic and microporous surface properties. The material is chemically inert and is available in varying thicknesses and strength profiles.

Typical indications include TAA/AAA grafts, peripheral vascular and endovascular stents

Covering Materials include:

- PET

- UHMWPE (Dyneema)

- Nylon

- PTFE

- Polyurethane

- Silicone

- PU-Sil